Polamer Precision’s dedicated development team provides early-on collaborative interaction with the client’s engineering team allows us to concurrently develop the most suitable engineering strategies. This direct collaboration inherently maximizes efficiency while minimizing costs during the manufacturing process. Co-development of programs for components has many benefits. We invest in cells to foster high-rate production and ability to scale.

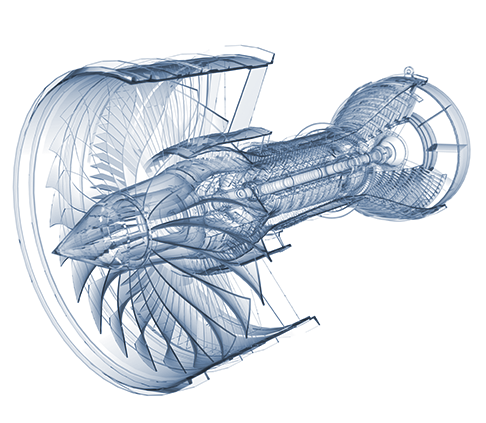

Our target market is prime manufacturers seeking manufacturing of complex aerospace engine components including, but not limited to: cases, split cases, ducts, diffuser cases, bearing housings, etc.

Target specifications: 3’ – 6’ cubes round in shape with processes that include 3, 4, and 5-axis milling, turning, assembly, and FPI (fluorescent penetrant inspection).